Electrical prefabrication is a technique that allows engineers to drastically reduce the time and cost of making buildings with electrical systems. One compelling reason to have a prefabricated system is that it can be customized, saving both time and money.

In the past few years, electronic prefabrication has become integral in the electronic field, mainly with the growth of modular construction approaches. This article will discuss why electronic prefabrication is worthwhile in your organization.

Reasons Why Electrical Prefabrication Is worth in Your Construction Firm

1. Cost Saving

Compared to other conventional construction methods, prefabrication allows you to generate and manage files during the design, operation, and construction phases much more easily while reducing building costs. Generally, prefabrication entrails construct replicated field instruction tasks in the shortest time feasible.

Cost savings through prefabrication can be achieved in the following ways:

Lower Labor Costs

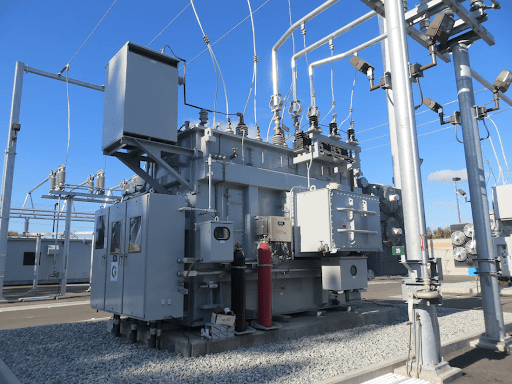

Prefabrication helps lowering labor costs by lowering installation errors, reworking, and preparing components prior to field installation. For instance, buying electronic prefabrication substation elements reduce the labor load on your electrical contracting firm while instilling the components.

Prefabrication reduces the amount of time it takes to build a project by eliminating the need for site visits by electricians and engineers. Much extra work is involved with pre-engineered buildings and their systems. This includes making new drawings, going onsite to adjust designs, making revisions to drawings, purchasing materials, wiring them, and testing every aspect of the system.

Reduce Material Costs

Prefabrication allows you to generate identical components for works and acquire materials in bulk with particular sizes or volumes. This is contrary to a traditional construction process where most materials are purchased in different forms and sizes. As a result, they may be trimmed to a specific form or size for installation. In most cases, unwanted pieces are frequently discarded.

Reduced Estimating Costs

Another area of cost reduction can be achieved in your electronic estimating software by using data gathered in the shop, including productivity and prefabricated data stored in fabrication shop software.

2. Time-saving

Prefabricated materials have almost no defects and need little scrutiny throughout the assembly. Workers use less energy and time implementing the project when the prefabricated pieces meet the required criteria. For example, a prefabricated substation may merely need connections and activation to function.

Unlike conventional construction approaches, prefabrication allows you to move faster once your building is designed. It also creates higher quality at a better speed because the workers can concentrate on fewer projects at once. As workers gain more experience setting and handling prefabricated materials, they begin working more resourcefully and consuming less time on installation.

Foundations for Successful Prefabrication Use in Electrical

When beginning to prefabricate parts within your organization, it is best to take safeguards and proceed with prudence. Always start with a few items while you study and assess the risks. A step-by-step plan will also indicate what works and what needs to be tweaked.

In most cases, the achievement or failure of prefabrication entirely depends on the project’s planning. Therefore, the result of your project is highly influenced by the individual’s knowledge about the project and the planning quality. Always pay closer attention to component specifications to reduce mismatches and tackle problems that arise during installation processes.

It is also paramount to understand and identify the three major prefabrication phases; panels, structural and modular construction. These three phases are equally employed in the construction of prefabricated substations.

The Future of Electrical Prefabrication

Although prefabrication is still relatively new to the electrical construction business, evidence is pointing to a bright future for the industry. Construction workers are eager to welcome this new process, which promises higher quality and less hassle.

Engineers develop more demanding and complex designs as construction methods continue to evolve. This requires large volumes of materials and a diverse labor force, increasing costs and construction time. Prefabrication address this concern, as they consist of fewer materials, require fewer workers, and can be assembled onsite in a timely manner. Due to these benefits, some companies have begun to include prefabricated electrical components.

Read More

Leave a comment